Hydrogen: A Key Component of Net-Zero Energy Systems

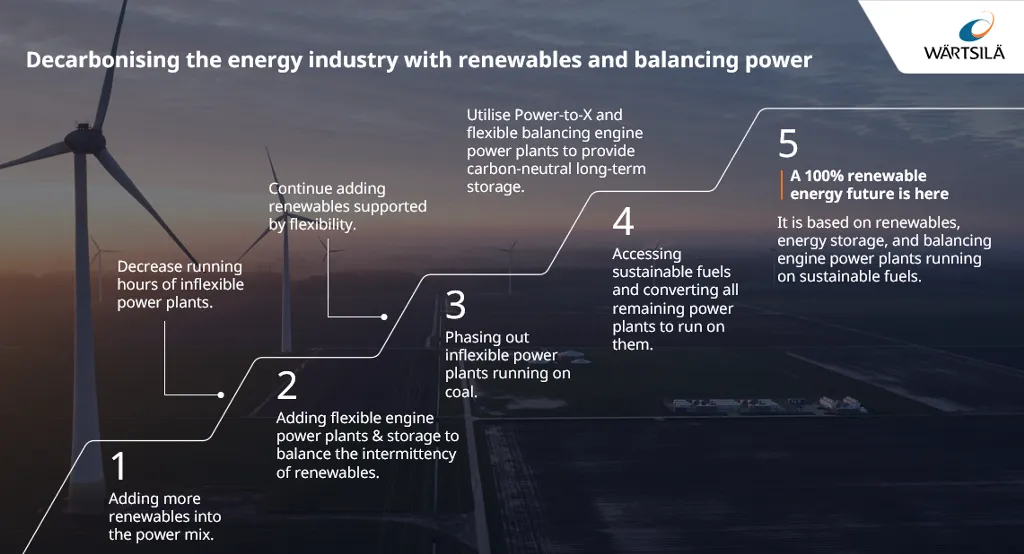

The world is moving toward a 100% renewable energy future and many significant strides have already been taken in the right direction. The final step on the journey toward decarbonization is the deployment of sustainable fuels in our energy systems.

The deployment of renewable energy resources around the world is set to double by the end of this decade. Because of the intermittent nature of renewable energy sources, like wind and solar power, they need to be balanced by flexible power-generation solutions (Figure 1). This has created the right conditions for excess clean electricity to be used in the production of hydrogen-based, carbon-neutral fuels.

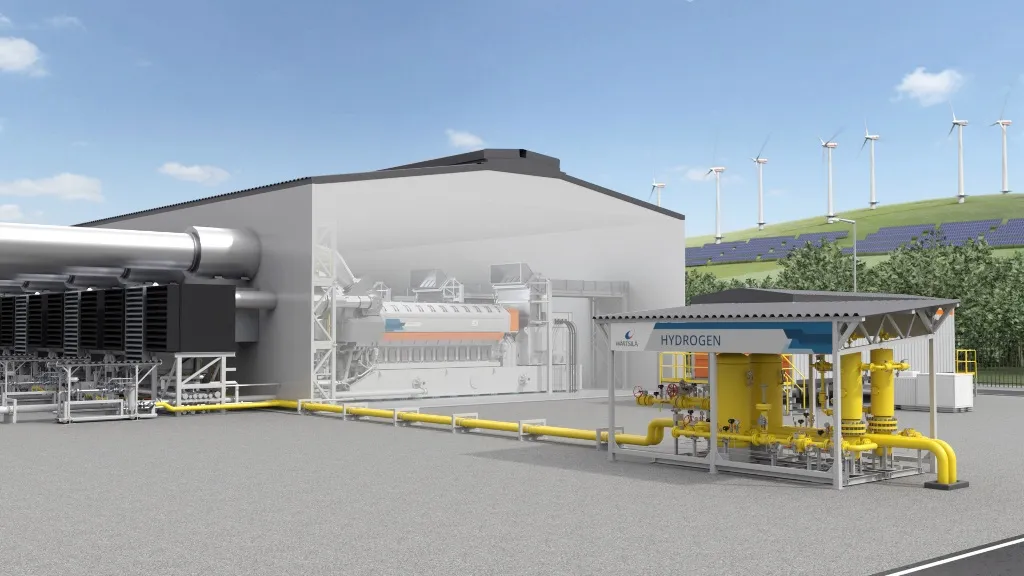

Engine power plants (Figure 2) are the optimal solution for balancing renewables. When fueled by green hydrogen, they make power production completely carbon-free. Wärtsilä’s hydrogen power plant solutions enable this 100% carbon-free power generation. This is allowing Wärtsilä’s customers in the energy sector to decarbonize by providing future-proof balancing solutions that are ready to run on sustainable fuels such as green hydrogen. Wärtsilä’s engines are also highly fuel efficient and have extremely fast ramp times with no minimum up or downtime, which means that they are operating optimally on the chosen fuel.

“Personally, I’m super excited to see how we have been able to combine our engine technology with our innovative experts to really achieve amazing results on these new fuels, including hydrogen,” said Rasmus Teir, head of Sustainable Fuels with Wärtsilä. “Fuels that we initially thought might be a big challenge to run on, now, we have really shown that it’s possible.”

Wärtsilä’s 100% Hydrogen Engine Power Plant Solutions

The heart of the Wärtsilä hydrogen-ready engine power plant is the Wärtsilä 31 engine platform—the most efficient engine of its type in the world. It is a highly proven engine platform and has more than a million running hours in the field. The Wärtsilä 31 engine is fuel flexible, which means that it can operate both on hydrogen and natural gas.

The first products brought to the market will be the 100% hydrogen-ready natural gas Wärtsilä 31SG-H2 engine (Figure 3) and the Wärtsilä 31H2 pure hydrogen engine. Wärtsilä’s hydrogen power plant solutions are available for tendering in 2025 and delivery in 2026.

How a Hydrogen Power Plant Works

Wärtsilä’s hydrogen power plants are based on a well-established gas power plant design. Hydrogen arrives at the power plant via pipeline from a hydrogen source. The pressure of the gas is reduced to a specific setpoint. The temperature of the hydrogen is constantly monitored and kept within limits. To ensure the purity of hydrogen, a treatment solution is used.

The fuel gas supply unit constantly controls the gas feed pressure to the hydrogen engine. Double-wall gas piping is used inside the engine hall for enhanced safety.

Thermal NOx is caused by a high combustion temperature inside the engine. If NOx reduction is required to comply with emission limits, a selective catalytic reduction (SCR) system is needed. It is recommended to place cooling radiators on the ground to ensure a free exit route for hydrogen through the engine hall roof monitors.

Safety Features

A hydrogen system leak test must be performed at possible leakage points utilizing a mixture of helium and nitrogen. This mixture is optimal for detecting leakages due to its similar molecular size to hydrogen.

A hydrogen fuel system requires inerting—where oxygen is removed before hydrogen is fed into the system. Nitrogen is used for this purpose. Inerting must be done during commissioning, and always before and after maintenance.

Hydrogen leak detection is conducted in several ways to alert personnel of potential danger. Detecting leaks at an early stage is important so they can be stopped and prevent larger problems. Multiple monitors are placed in critical places for this purpose.

A fire detection system is also important. It is designed to detect and report fires as early as possible. Thermal cameras can be used to detect possible hydrogen fires, which are invisible to the human eye. Closed-circuit television (CCTV) cameras can also be used to monitor different parts of the engine hall for safety issues.

Five Reasons to Choose Wärtsilä’s Hydrogen Power Plant Solution

- Proven Technology. The Wärtsilä 31 engine platform has clocked more than one million running hours and more than 1,000 MW of installed power capacity.

- A Strong Track Record. The hydrogen power plant solution has been developed based on more than 60 years of experience in introducing alternative fuels to the market and developing a large portfolio of fuel capabilities and fuel-flexible power plant concepts. Wärtsilä has been working with pure hydrogen concepts since 2021.

- Extensive Engine Conversion Experience. Wärtsilä has successfully converted more than 100 engines to run on new fuels.

- A Safe and Reliable Solution. Wärtsilä’s 31 hydrogen engine power plant concept has been certified by TÜV SÜD—a leading global provider of testing, certification, auditing, and advisory services—demonstrating Wärtsilä’s commitment to quality and safety.

- The Optimal Technology for Balancing. Wärtsilä’s hydrogen power plant solutions (Figure 4) are highly efficient and have extremely fast ramp times with no minimum up or downtime so customers can use valuable green hydrogen fuel in the most optimal and efficient way.

“Engine power plants are highly efficient. They can be started and stopped at will. They can ramp up quickly. All this means that you can utilize your high-value sustainable fuels in the most optimal and efficient way,” said Teir. “These capabilities come in handy now, as energy transition will require transition to sustainable fuels.”

“We must be realistic that natural gas will play a part in our power systems for years to come,” said Anders Lindberg, president of Wärtsilä Energy. “Our fuel flexible engines can use natural gas today to provide flexibility and balancing, enabling renewable power to thrive. They can then be converted to run on hydrogen when it becomes readily available: future-proofing the journey to net zero.”

“We are not at the finishing line yet, but we are ready to take the needed steps toward a 100% renewable energy future,” Teir concluded.