Marnie Surfaceblow: Bowing Under Pressure

Long-time POWER readers may remember Marmaduke Surfaceblow, a fictional character whose engineering escapades were brilliantly portrayed in hundreds of stories published within POWER magazine’s pages over more than 30 years beginning in 1948. Today, the fictional series continues through Marmy’s granddaughter, Marnie, who is an engineering wiz in her own right.

____

Just because something hasn’t failed doesn’t mean it won’t—especially when an “old dog” of a plant is taught new tricks.

Two women wearing personal protective equipment waited impatiently in the shade of a guard hut on an unusually warm Canadian summer morning. Slapping her forearm to kill a mosquito that had started drilling for blood like a tiny oil derrick, Marnie Surfaceblow, vice president of Surfaceblow & Associates International, was at her wits’ end. “They say there are two seasons in Canada, my faithful apprentice—winter and mosquito. I think that makes bite number 500 from these Lilliputian vampires. And how come they aren’t bothering you?” she remarked to her assistant.

Maya shrugged. “I am Indian. Our strength and honor cannot be overcome by mere mosquitos. Also, insect repellent.”

Marnie nodded. “Your foresight favors fortune. And Saint Sara be praised, our hosts have arrived to rescue us!”

|

|

1. Marnie and Maya are greeted by Preston and Annik at the coal plant’s front gate. Source: POWER |

They were greeted very warmly by the plant manager, Preston McDonald, and the chief engineer, Annik Ivanoff, who offered the mercy of an air-conditioned ride to the old coal power station (Figure 1), which was having some problems converting to biomass fuel. As they made the usual pre-work small talk, Maya asked Annik, “By your family name, Ivanoff, are you Russian?”

“Inuit, and two-spirit,” replied Annik. “Many from Alaska have Russian names from the occupation. My chosen name means ‘grace.’ ”

“Well that’s fairly fortuitous!” announced Marnie with glee. “My name and Maya’s mean joy, and with yours meaning grace, hopefully we’ll all have good luck! Preston, what does your name mean?”

Preston smiled, “Oh, shoot, I don’t know. Maybe ‘he who has more problems than mosquitos,’ eh?”

“Well, I can’t do anything about the mosquitos—darn it, speak of the devil!” Marnie slapped her arm again, claiming another insect victim, “but I’ll bet we can help get rid of your problems.”

Unveiling the Plant Puzzle

The morning briefing was well-attended by friendly and highly engaged plant staff, who were clearly hoping for good news from the visiting consultants. The usual introductions were made and business cards exchanged. Marnie took a four-liter carton of Tim Hortons’ coffee from her backpack and started pouring a cup.

“Well, thank you so much for bringing us all coffee, ma’am. I’ll go get some more cups,” said one of the engineering interns. Marnie sat in mute horror, until Maya leaned over and whispered, “Ma’am, it will work out. I anticipated such, and have hidden an extra liter of coffee in my backpack for you.” Marnie turned and stared at Maya, and whispered, “Remind me to give you a raise when we get back to the office.”

When all had taken a cup of Marnie’s figurative lifeblood, and Maya had surreptitiously passed the full liter carton to Marnie under the table, Preston started the meeting.

“We started burning local coal in 1949, sending 400 MW almost 24/7 onto the grid. The plants mostly standard design—subcritical balanced-draft, five mills with one kept spare, each mill feeds one burner level. We have two electrostatic precipitators, no other emissions control systems. And the plant was reliable, running smooth until the powers that be said we had to stop burning coal within eight years. We’re natural gas poor in this province an’ no pipelines to bring enough in. There’s local hydroelectric power, see, but some energy trader sold all the extra to the States for a decade! If this plant shuts down, we can’t make it through the winter without brownouts or shutting down industries,” he explained.

Maya flipped through some briefing pages, and commented, “And while you could deploy demand-side management plans, my research shows two aluminium smelters are your largest contracted customers. Those customers often require baseload power, so your flexibility is limited.”

“Well, we found a white knight,” Preston replied. “There’s a wood pellet producer nearby using partial thermal upgrading to make pellets we can get by on. We derate by 200 MW from poor mill grindability, but they’re relatively cheap.”

Marnie, flipping through fuel quality data sheets, replied, “Hmph. Maybe. Given the cost per tonne, I mean, you could truck pellets from elsewhere cheaper.”

“We looked,” replied Annik, “but you know what the pellet market looks like? There’s waiting lists two years out for pellets we could use.”

Marnie shrugged. “So … they’re not carbonizing the pellets very much, and their bulk density implies a worn pelletizer. This bulk density of 550 kilograms per cubic meter [kg/m 3 ] wouldn’t pass muster in some countries. Your local coals have a density of about, what, 800 to 850 kg/m 3? No way that doesn’t cause problems.”

“Nope, it’s definitely part of the problem,” Annik shook her head and continued, “Just lightly cooking the pellets doesn’t really help energy density, so the pellet heating value is two-thirds that of coal. At 200 MW, we burn eight more tonnes of pellets per hour than we burn of coal at 400 MW. Being mostly small cylinders, the pellets have more void space than coal. Our two main plant feed conveyors have a 27-degree hoist, and pellets roll back down the belt and spill—being small cylinders on moving equipment. We started water misting to increase pellet adhesion, and it genuinely helped, but not near enough to reach more than half capacity.”

Jeff Clinton, a grizzled fuel-handling engineer, spoke up. “We have separate silos per mill, rather than a single divided bunker. Since the pellets don’t grind good, we send them to the three middle mills. We add coal at the bottom or top mills to help combustion. Each silo holds 16 hours of coal, but under eight hours’ worth of pellets, even at half plant output. Our main conveyors run almost constantly, mostly moving pellets. Our coal bins sit filled to the brim unless we have an emergency call for power.”

“You no longer require the coal mills for combustion stability?” asked Maya.

Shaking his head, Preston replied, “We upgraded systems and controls, and monthly fine-tune and maintain the mills, so things mostly work out—unless it rains on the pellets, and then we will bring in the coal mills. But let’s let Jeff show you our biggest problem, and it’s a doozy, folks!”

Jeff reached into a duffel bag and retrieved two massive steel chain links that were twisted and broken. “This plant was built with a continuous scraper conveyor to feed the fuel silos. It’s basically a drag-chain with steel blades pulling the fuel along a steel trough to drop it down the five silo hatchways. The first hatchway feeds silo #1 that feeds the lower coal mill, and the last hatchway in the run feeds silo #5, the upper coal mill. Pellets are sent through the middle three hatchways.” Jeff paused and shook his head. “Ladies, I’ve worked here nigh on 40 years and never seen any conveyor problem like this. During the two-mill tests, I saw high conveyor motor amperage, and running three pellet mills we hit the amperage limits at least once a day. And then two weeks ago, two of our drag chain links broke! We fixed them, and last week another link broke. This thing’s so old these links are custom-crafted, and we are out of spares.”

“Also,” Annik leaned in, “last week, during feeder cleaning, we found small steel shavings mixed in with the pellets. It looks like it’s coming from the conveyor trough, but why? The pellets aren’t that abrasive. So … what do you think?”

From Family Lore to Engineering Solution

The group looked to Marnie and Maya, waiting for an answer. Marnie held her coffee cup with deep reverence, gazing down into its milky depths as if reading the plant’s fortune. Knowing her boss’s mind was running full-tilt, Maya started asking operations and maintenance questions, logistics on getting a plant distributed control system data dump, and about the water mist system. All questions soon had answers, and Maya had no choice but to nudge her boss and ask, “Ma’am? What is it you ponder?”

“I was thinking of the stories told by my family. I wanted to be a writer, an artist, a musician, and many other things, but I listened to every story of engineering exploits and derring-do, and I remember them all.” Marnie turned toward Maya and tapped her own head. “I was recalling a story from Grandpa Marmaduke. He was on a Mississippi steamboat pleasure cruise, playing poker and drinking his sandpaper gin, until he had to help fix an anchor chain that kept mysteriously breaking. And then in another story …”

Suddenly, Marnie stood and addressed the room, green eyes flashing with inspiration. “Memory and experience are invaluable, and when combined with measurement, analysis, and applied research solutions, it creates the noble and honorable practice of engineering!”

Silence reigned as Marnie continued. “And thus, your stories brought forth from the depths of my mind another tale, and led to a theory. I have a shopping list, but since my personal shopper is about 2,000 miles away, I must instead ask you good folks for help. We need laser levels and silo weight tracking charts. I want to see the metal shavings mixed with the pellets, and all data from the two days prior to each scraper conveyor failure. Maya, let’s start looking through the data, then armed with some lasers—Wow, that sounds really cool!—we’ll inspect the scraper conveyor in its natural habitat.”

Finding Order Amid the Chaos

Plant data collection was managed by dozens of systems, from circular chart pen-and-paper recorders to broad-spectrum wireless transceivers. Even Maya, whom Marnie sometimes called “the Devi of Data,” struggled to weave her virtual tapestry of daily plant performance. “Ma’am, I confess, I am feeling like a translator at the United Nations who was assigned all the wrong countries. The plant documentation, it is English, French, at least one First Nations language, and I believe this is … Portuguese? But worst of all, ma’am, every microcontroller is set to a different time—sometimes a different date or year! No two of them agree. Perhaps they should synchronize with the phases of the moon!”

“Don’t you dare suggest that,” hissed Marnie. “I once had to set a continuous emissions monitoring system to use the lunar calendar. It’s required, really, for power plants operated by werewolves.” Stunned at being caught off-guard by Marnie’s deadpan, which normally Maya was used to, she laughed refreshingly, and said, “Exceedingly good, ma’am.”

Setting down a bag full of borrowed laser levels, Marnie could no longer control herself, and clapped her hands with glee. “Have you looked around this place? This plant is positively steampunk! One conveyor control box uses vacuum tubes AND gutta percha wiring! I found five oil pressure gauges working off Bourdon tubes! Their feedwater heaters have bronze Art Deco isolation valves! This plant is so old, it’s been retro twice!”

Maya sighed and pinched the bridge of her nose. Marnie, realizing her exuberance was out of place, quietly said, “I have all the gear we need. How can I help?”

Maya passed her laptop over, and replied, “Ma’am, please examine these data trends and see if you are finding the same patterns as I?” Giving the data her full mental focus, Marnie checked every calculation, then looked up, her face showing controlled alarm. “Is it safe?”

Giving Marnie “The Look,” Maya said, “Ma’am, if I did not believe so, would I be calmly sitting here?” Sheepishly, Marnie returned to reviewing, then gave a quick nod. “Everything lines up. Very well done! You did the improbable.”

“Do you not mean the impossible?” asked Maya.

“Well, you did it, thus by definition it wasn’t impossible,” replied a beaming Marnie. Maya shook her head. “You’re impossible.”

Illuminating the Problem

An hour later, they joined the plant staff in the scraper conveyor room over the fuel silos. Preston greeted them, wiping a mixture of biomass and coal dust from his face. “We found signs the scraper conveyor was, well, scraping the fuel trough, mostly between silos 2 and 4. Jeff says he’s never seen the like!”

|

|

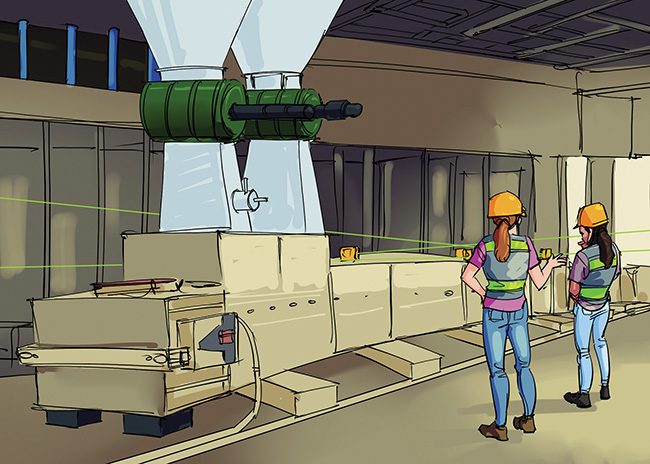

2. Marnie and Maya used laser levels to help identify the problem in the scraper conveyor room. Source: POWER |

Maya took notes and interviewed coal maintenance personnel, while Marnie, eager as a kid on Christmas Day, was running about setting up laser levels (Figure 2). “Maya! Remind me to buy some of these! In green!”

“Green laser light, ma’am, or green in housing color?” Maya asked distractedly. “Both!” was Marnie’s enthusiastic reply.

Maya confirmed the level placement, making one final adjustment, while Marnie stationed staff at each laser level. She returned to the center of the conveyor room and yelled, “Fiat lux!”

Seeing puzzled looks from the plant staff, Maya yelled, “Kindly turn on the laser levels! Thank you!” The scraper conveyor room suddenly was crisscrossed with six fans of oscillating green beams, immediately revealing that the entire conveyor room floor was bowed upward.

Preston gaped incredulously, while Annik ran to read the digital measurements. She rose and shook her head, saying, “But … how? The scraper conveyor trough is almost 20 centimeters higher at the center than at hatchway #1, and about 10 centimeters higher than it is at hatchway #5? Is this normal?”

“Nope, not by a long shot,” replied Jeff. “We measure the sag in this room twice a year, and it normally tends to dip about five to 10 centimeters in the middle. How on earth …”

“… do we get more coffee up here,” interrupted Marnie. “That, my friends, is a question unanswerable by mere mortals, such as I. But, we can tell you what’s going on with the floor.”

Leveling the Playing Field

“I had one idea about the conveyor problems from the steamboat anchor chain story. In that case, a new cargo master was atrociously loading the hold, torquing the ship structure. This bowed the deck upward, pinching the anchor chain and eventually breaking it. Then I recalled another story,” Marnie explained. “A grain silo with 2,000 tonnes of oats slowly filled with 1,000 tonnes of water from a leaking sprinkler. The added weight dragged the silo down almost two meters before it failed. No one was injured, but 3,000 tonnes of oatmeal makes the most dreadful mess!”

Enjoying being the center of attention, while Maya started already pricing parts, Marnie continued. “It’s a question of balance. Jeff, you said the coal silos hold about 16 hours at full output—I figured that at about 600 tonnes each. But for the pellet silos, adjusting for fuel density, heat content, and plant efficiency differences, a full pellet silo barely weighs half what a coal silo does. So, with relatively heavy full coal silos on either end of the room, not only are they sagging, but they’re also bending the floor and fuel trough upward in the middle.”

“This might not have been critical, but there were complications,” added Maya. “This partly charred wood pellet fuel is much more plastic than torrefied pellets, and it can build a layer between the scraper blades and the trough, until it forms a solid wedge. This presents significant resistance to the scraper conveyor movement, increasing the motor amperage. And when you started wetting the pellets to help them stick to the main conveyor belts, this accelerated the buildup and increased the resistance to movement. We found many trends of scraper conveyor motor amperage increases corresponding with both your water misting and the silo loading.”

“Your scraper conveyor is tough, I’ll grant you that,” said Marnie, “but it’s not made of adamantium. At some point this biomass buildup, combined with traversing the upward bowing of the floor, was going to break the chain.”

There was general agreement and nodding, and work teams broke into groups to discuss potential hazards from the new findings. Preston and Annik stood with Marnie and Maya. “Let me guess,” said Preston, “this is going to be expensive, eh?”

“The answer is ‘yes-with-an-if’ or ‘no-with-a-but,’ ” Marnie said with a grin. “First, eliminate the wetting mist and install variable-speed drives on your main feed conveyors. I think you’ll find at half the speed you’ll actually end up with about twice the capacity. Importantly, less water means less buildup under the scrapers. These lightly cooked pellets usually rely on binders to reduce fines, and it looks like the binders work well for a little rain, but soon wash out and form deposits in your conveyor track.”

“Next, since you mostly solved the pellet grinding issues, must both coal silos stay so full?” Marnie asked. “How much load-shifting power reserve do you need? I’ll bet you can get by with eight hours, so keep the coal silos half to two-thirds full. That should equalize out the loading on the local superstructure and keep the flooring much more level.”

Tapping away on her tablet to tabulate costs, Maya added, “If you are willing to invest in greater reliability, you can purchase replacement conveyor belts with regular ridges on them to assist in moving material. They can be dear, especially on older power stations, but they do indeed work.”

“Worst case, we would need to beef up the coal silo and scraper conveyor structure, if you have about $10 to $20 million to spend. I’d get a bonus—and a BMW M5 has caught my eye—however,” Marnie sighed exaggeratedly, “even though I’d achieve annual sales targets early, I can’t ethically recommend something that major without trying some cheaper and potentially better options first.”

Thrown by Marnie’s deadpan humor, there was a brief pause before both Preston and Annik burst out laughing. “Thank you, Ms. Surfaceblow, Ms. Sharma. Let’s talk about some of the cheaper options first.” Following their hosts as they returned to the meeting room, and while riding the plant elevator to the first floor, Marnie whispered to Maya, “Rats, I really wanted that BMW.”

After the elevator stopped and while continuing their walk to the plant offices, Maya patted Marnie’s shoulder and said, “There, there, ma’am. Do not be unhappy. I ordered you a set of green laser levels as a gift, and yes, their housing is green as well.” Marnie’s joyous shout echoed through the plant.

—Una Nowling, PE is an adjunct professor of mechanical engineering at the University of Missouri-Kansas City.