Groups Collaborate to Electrify Chemical Processing Plants

Three major chemical processing companies announced the startup of a demonstration plant to show the viability of large-scale electrically heated steam cracking furnaces.

BASF, SABIC, and Linde on April 17 said the facility, at BASF’s Verbund site in Ludwigshafen, Germany, will begin operating after three years of development, engineering, and construction work. The three groups in March 2021 signed an agreement to jointly develop and demonstrate solutions for electrically heated steam cracking furnaces.

The companies in a news release wrote, “Steam crackers play a central role in the production of basic chemicals and require a significant amount of energy to break down hydrocarbons into olefins and aromatics. Typically, the reaction is conducted in furnaces at temperatures of about 850 degrees Celsius. Up to now, these temperatures have been reached by using conventional fuels. The demonstration plant aims to show that continuous olefin production is possible using electricity as a heat source. By using electricity from renewable sources, the new technology has the potential to reduce CO2 emissions of one of the most energy-intensive production processes in the chemical industry by at least 90% compared to technologies commonly used today.”

Want to learn more about how electrification is transforming the power generation and industrial sectors? Register now and join POWER, along with experts on electrification, at the P3 Electrified Summit in San Diego, California, Sept. 17-18, 2024.

Those groups’ announcement came one day after Lummus Technology, a global provider of process technologies and value-driven energy solutions, and Braskem, the largest bio-based polymer producer in the world, on April 16 said they will work on joint studies related to the industrial demonstration of Lummus’ SRT-e electric cracking heater. The technology will be used to decarbonize one of Braskem’s sites in Brazil.

The companies said the project “will set the basis for the eventual negotiation between Lummus and Braskem of a definitive agreement that will, among other things, establish the general guidelines by which such implementation will take place.”

Ludwigshafen Demonstration Plant

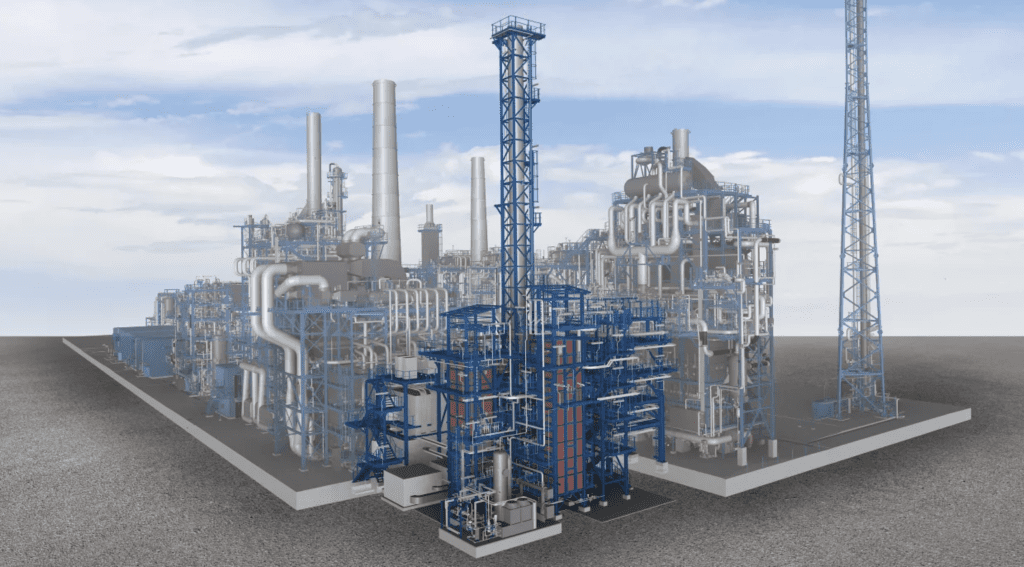

The demonstration plant in Germany will produce olefins, including ethylene and propylene, and also could make higher olefins from saturated hydrocarbon feedstock. The facility is fully integrated into the existing steam crackers at the Ludwigshafen site, which serves as BASF’s headquarters.

The groups said the demonstration plant will gather “data and experiences about material behavior and processes under commercial operating conditions for the final development of this innovative technology to industrial market maturity.” The plant has two separate demonstration furnaces, and each will test a different heating concept. Direct heating applies an electric current to the cracking coils in one furnace. The second furnace features indirect heating, using radiative heat of heating elements located around the coils.

The companies said two furnaces together will be able to process about four tons of hydrocarbon feedstock hourly, and consume 6 MW of energy from renewable resources.

The project’s development was supported by a €14.8 million ($15.8 million) grant from the German Federal Ministry for Economic Affairs and Climate Action under its “Decarbonization in Industry” funding program. The program is supporting energy-intensive industries in Germany that are working to achieve carbon neutrality.

“With the development of electrically operated steam cracking furnaces, we are getting our hands on a key technology that will help to significantly reduce greenhouse gas emissions in the chemical industry,” said Dr. Martin Brudermüller, chairman of the board of executive directors of BASF SE. “It fills me with pride and joy that we have achieved this success together with our partners SABIC and Linde. The demonstration plant here in Ludwigshafen will provide us with valuable experience on the final step towards the industrial application of this technology.”

SABIC CEO Abdulrahman Al-Fageeh said, “The e-furnace’s technology holds huge potential for the sustainability of the global petrochemical industry. It can demonstrate the role that renewable electricity can play in higher efficiency and low-emission chemical processing. Through close collaboration, teamwork, intellectual property development, and advancing the best technical solutions holistically, the teams at SABIC, BASF and Linde have brought this project to this key stage. We are proud to be here together today to celebrate the power of collective action on our journey toward a circular carbon economy.” SABIC is headquartered in Saudi Arabia.

The Ludwigshafen demonstration plant will be operated by BASF. Linde, based in Dublin, Ireland, was responsible for the engineering, procurement, and construction of the plant. Linde will commercialize the developed technologies at the facility under the new trademark STARBRIDGE, which is designed to help the petrochemical industry decarbonize by replacing conventional-fired technologies that have been supported by fossil fuels.

“It is our common goal to demonstrate that it is possible to electrify the petrochemical industry and to operate a steam cracker with sustainably generated electricity,” said Jürgen Nowicki, CEO of Linde Engineering. “This outstanding joint project is a significant proof of how together we can develop groundbreaking technologies that will advance us on the journey towards net-zero CO2 emissions and climate-neutral industry. The STARBRIDGE technology brings the vision of an emission-free petrochemical industry a step closer.”

Decarbonize Brazilian Ethylene Facility

The project at the plant in Brazil, using the SRT-e electric cracking heater, “leverages Lummus’ proven Short Residence Time (SRT) technology modified to operate using electricity and incorporates a modular unit-cell design that can be replicated for plants to accommodate any commercial capacity,” according to a news release. Lummus and Braskem officials said the technology “uses all commercially demonstrated components, plus an optimum heat flux profile leading to a longer radiant coil life and longer run length. In addition, decoking can be carried out on a unit-cell basis so maintaining a spare heater is not required.”

“The selection of Lummus’ SRT-e electric cracking heater as a means to decarbonize Braskem’s ethylene plants are founded on a shared commitment to develop and implement profitable sustainable technologies and solutions,” said Jose de Barros, vice president and managing director of ethylene for Houston, Texas-based Lummus Technology. “We look forward to demonstrating our breakthrough electrification technology that drastically reduces greenhouse gas emissions.”

Braskem, headquartered in São Paulo, Brazil, has a goal to reduce its greenhouse gas emissions by 15% percent by 2030. The company wants to be carbon-neutral by 2050. Braskem operates 40 industrial units in Brazil, the U.S., Mexico, and Germany, and exports its products to more than 70 countries.

“Our ambition is to considerably reduce CO2 emissions and increase the sustainability of our products through innovation, in-house developments, and important partnerships. Lummus’ SRT-e technology will help Braskem achieve its goal of carbon neutrality by 2050, which will help increase energy efficiency at our crackers,” said Antonio Queiroz, Braskem VP for Innovation, Technology and Sustainable Development. “Expanding the use of renewable electricity and renewable materials will enable Braskem to reduce its carbon footprint in the production of ethylene, propylene and other chemicals.”

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).